How is RFID Asset Tracking Different from Other Asset Tracking Solutions?

Asset tracking is a critical component of efficient business operations, and various technologies are available to help organizations manage their assets effectively. Among these, RFID (Radio Frequency Identification) asset tracking stands out as a powerful and versatile solution. But how does it differ from other asset tracking methods, such as barcode scanning, GPS tracking, or manual tracking? Let’s explore the key differences and advantages of RFID asset tracking. 1. Automation and Efficiency RFID Asset Tracking: RFID systems use radio waves to automatically identify and track assets equipped with RFID tags. Unlike barcodes, RFID does not require line-of-sight scanning. This means multiple assets can be scanned simultaneously, even if they are inside containers or hidden from view. This automation significantly reduces the time and labor required for asset tracking. Other Solutions: Barcode tracking requires manual scanning of each asset, which can be time-consuming and prone to human error. GPS tracking is useful for outdoor assets but is less effective for indoor or densely packed environments. Manual tracking, such as spreadsheets, is highly inefficient and error-prone. 2. Real-Time Visibility RFID Asset Tracking: RFID provides real-time visibility into asset locations and status. Fixed or handheld RFID readers can continuously monitor assets as they move through different locations, enabling instant updates to the system. This is particularly valuable for high-value or mission-critical assets. Other Solutions: Barcode tracking only provides data at the point of scanning, offering no real-time updates. GPS tracking offers real-time location data but is limited to outdoor use. Manual tracking relies on periodic updates, which can lead to outdated or inaccurate information. 3. Scalability RFID Asset Tracking: RFID systems are highly scalable and can track thousands of assets simultaneously. This makes them ideal for large organizations with extensive asset inventories, such as warehouses, hospitals, or manufacturing facilities. Other Solutions: Barcode tracking can become cumbersome as the number of assets grows, requiring more time and resources to scan each item. GPS tracking is less practical for large-scale indoor asset management. Manual tracking becomes increasingly inefficient as the volume of assets increases. 4. Durability and Flexibility RFID Asset Tracking: RFID tags are durable and can withstand harsh environments, including exposure to dust, moisture, and extreme temperatures. They can also be embedded within assets, making them less susceptible to damage or tampering. Other Solutions: Barcode labels are prone to wear and tear, and their readability can be compromised if they are damaged or dirty. GPS devices are typically bulkier and may not be suitable for small or delicate assets. Manual tracking relies on physical records, which can be lost or damaged. 5. Data Capacity and Integration RFID Asset Tracking: RFID tags can store more data than barcodes, including unique identifiers, maintenance history, and other relevant information. This data can be easily integrated with enterprise systems like ERP or asset management software, enabling seamless workflows and better decision-making. Other Solutions: Barcodes have limited data capacity and typically only store a unique identifier. GPS tracking focuses primarily on location data and may not integrate as effectively with other systems. Manual tracking relies on manual data entry, which is slow and prone to errors. 6. Use Cases and Applications RFID Asset Tracking: RFID is ideal for industries that require high-speed, high-volume asset tracking, such as retail, healthcare, logistics, and manufacturing. It is also well-suited for tracking assets in challenging environments, such as construction sites or oil rigs. Other Solutions: Barcode tracking is commonly used in retail and inventory management but is less effective for dynamic or high-volume environments. GPS tracking is best for outdoor assets like vehicles or heavy machinery. Manual tracking is typically used in small businesses with limited assets. Conclusion RFID asset tracking offers a unique combination of automation, real-time visibility, scalability, and durability that sets it apart from other asset tracking solutions. While the initial investment may be higher, the long-term benefits in terms of efficiency, accuracy, and cost savings make RFID an attractive option for businesses looking to optimize their asset management processes. However, the choice of asset tracking solution ultimately depends on your specific needs, budget, and operational environment. For organizations with large, dynamic, or high-value asset inventories, RFID is often the best choice. For smaller-scale operations or outdoor tracking, barcode or GPS solutions may be more appropriate. If you’re considering implementing an RFID asset tracking system, it’s important to evaluate your requirements and choose a

Asset tracking is a critical component of efficient business operations, and various technologies are available to help organizations manage their assets effectively. Among these, RFID (Radio Frequency Identification) asset tracking stands out as a powerful and versatile solution. But how does it differ from other asset tracking methods, such as barcode scanning, GPS tracking, or manual tracking? Let’s explore the key differences and advantages of RFID asset tracking.

1. Automation and Efficiency

RFID Asset Tracking:

RFID systems use radio waves to automatically identify and track assets equipped with RFID tags. Unlike barcodes, RFID does not require line-of-sight scanning. This means multiple assets can be scanned simultaneously, even if they are inside containers or hidden from view. This automation significantly reduces the time and labor required for asset tracking.

Other Solutions:

Barcode tracking requires manual scanning of each asset, which can be time-consuming and prone to human error. GPS tracking is useful for outdoor assets but is less effective for indoor or densely packed environments. Manual tracking, such as spreadsheets, is highly inefficient and error-prone.

2. Real-Time Visibility

RFID Asset Tracking:

RFID provides real-time visibility into asset locations and status. Fixed or handheld RFID readers can continuously monitor assets as they move through different locations, enabling instant updates to the system. This is particularly valuable for high-value or mission-critical assets.

Other Solutions:

Barcode tracking only provides data at the point of scanning, offering no real-time updates. GPS tracking offers real-time location data but is limited to outdoor use. Manual tracking relies on periodic updates, which can lead to outdated or inaccurate information.

3. Scalability

RFID Asset Tracking:

RFID systems are highly scalable and can track thousands of assets simultaneously. This makes them ideal for large organizations with extensive asset inventories, such as warehouses, hospitals, or manufacturing facilities.

Other Solutions:

Barcode tracking can become cumbersome as the number of assets grows, requiring more time and resources to scan each item. GPS tracking is less practical for large-scale indoor asset management. Manual tracking becomes increasingly inefficient as the volume of assets increases.

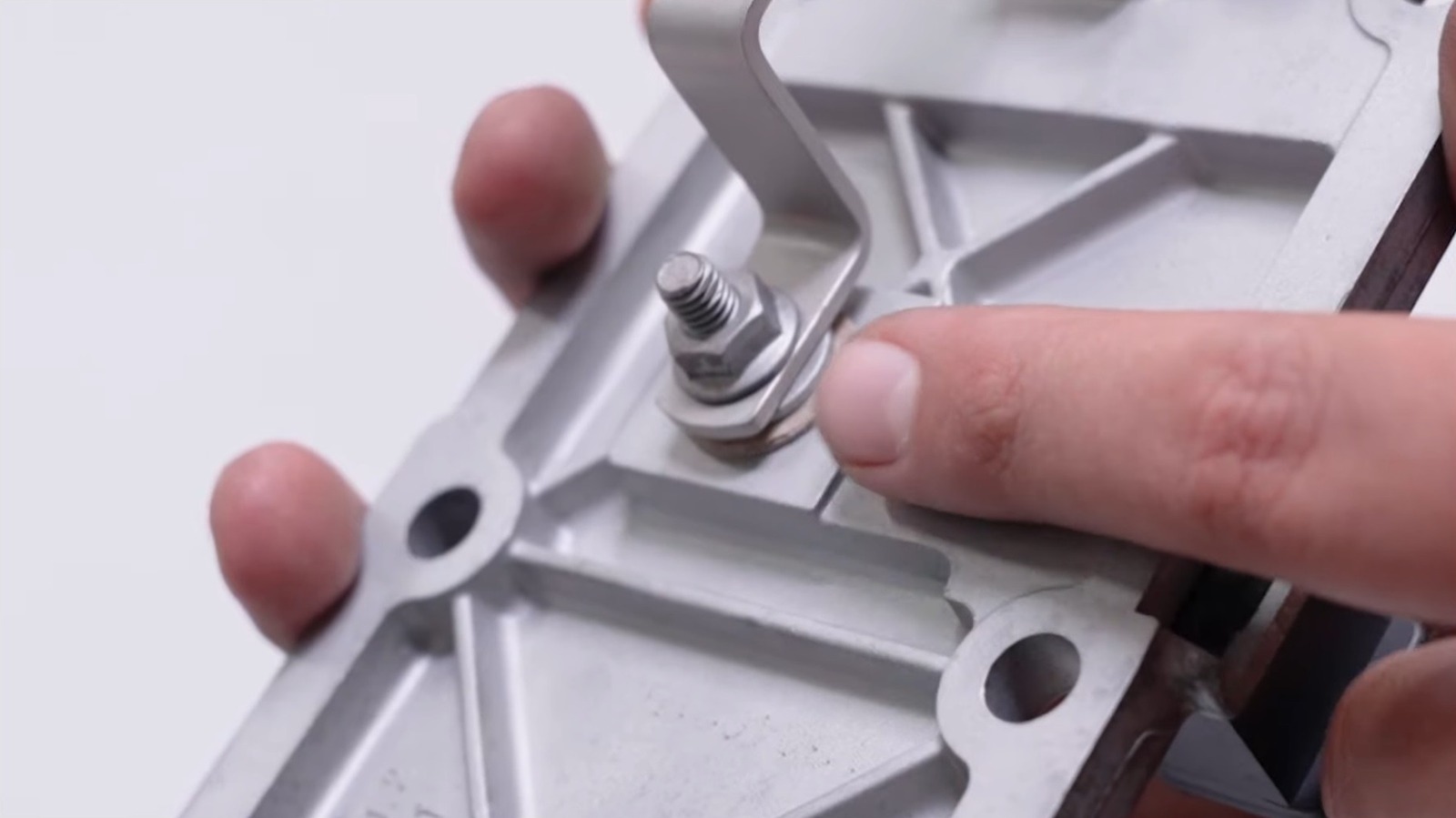

4. Durability and Flexibility

RFID Asset Tracking:

RFID tags are durable and can withstand harsh environments, including exposure to dust, moisture, and extreme temperatures. They can also be embedded within assets, making them less susceptible to damage or tampering.

Other Solutions:

Barcode labels are prone to wear and tear, and their readability can be compromised if they are damaged or dirty. GPS devices are typically bulkier and may not be suitable for small or delicate assets. Manual tracking relies on physical records, which can be lost or damaged.

5. Data Capacity and Integration

RFID Asset Tracking:

RFID tags can store more data than barcodes, including unique identifiers, maintenance history, and other relevant information. This data can be easily integrated with enterprise systems like ERP or asset management software, enabling seamless workflows and better decision-making.

Other Solutions:

Barcodes have limited data capacity and typically only store a unique identifier. GPS tracking focuses primarily on location data and may not integrate as effectively with other systems. Manual tracking relies on manual data entry, which is slow and prone to errors.

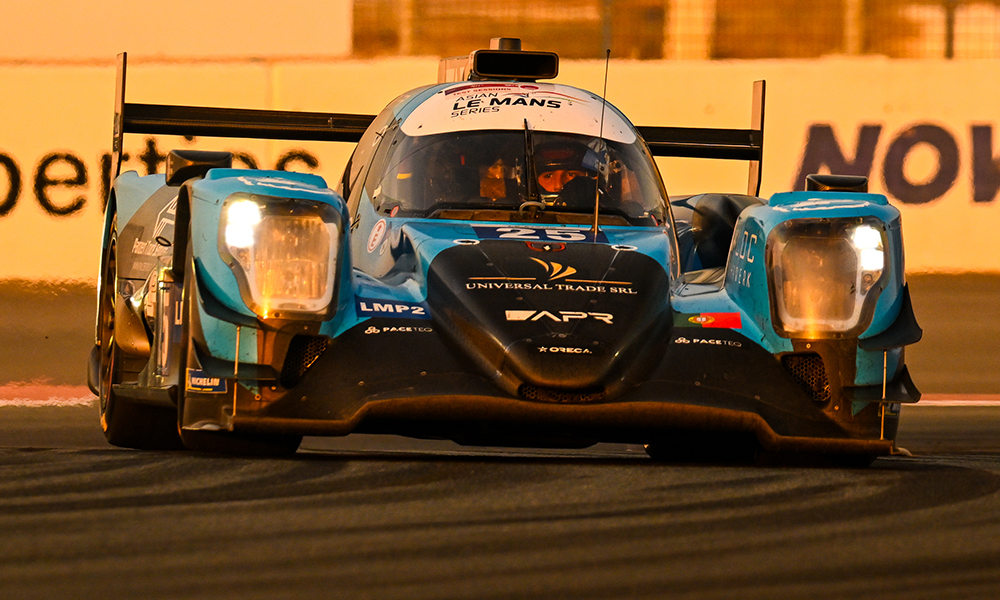

6. Use Cases and Applications

RFID Asset Tracking:

RFID is ideal for industries that require high-speed, high-volume asset tracking, such as retail, healthcare, logistics, and manufacturing. It is also well-suited for tracking assets in challenging environments, such as construction sites or oil rigs.

Other Solutions:

Barcode tracking is commonly used in retail and inventory management but is less effective for dynamic or high-volume environments. GPS tracking is best for outdoor assets like vehicles or heavy machinery. Manual tracking is typically used in small businesses with limited assets.

Conclusion

RFID asset tracking offers a unique combination of automation, real-time visibility, scalability, and durability that sets it apart from other asset tracking solutions. While the initial investment may be higher, the long-term benefits in terms of efficiency, accuracy, and cost savings make RFID an attractive option for businesses looking to optimize their asset management processes.

However, the choice of asset tracking solution ultimately depends on your specific needs, budget, and operational environment. For organizations with large, dynamic, or high-value asset inventories, RFID is often the best choice. For smaller-scale operations or outdoor tracking, barcode or GPS solutions may be more appropriate.

If you’re considering implementing an RFID asset tracking system, it’s important to evaluate your requirements and choose a solution that integrates seamlessly with your existing workflows. The right system can transform your asset management processes, driving efficiency and delivering measurable ROI.