Any suggestion to prevent the wire from snapping off at the hole?

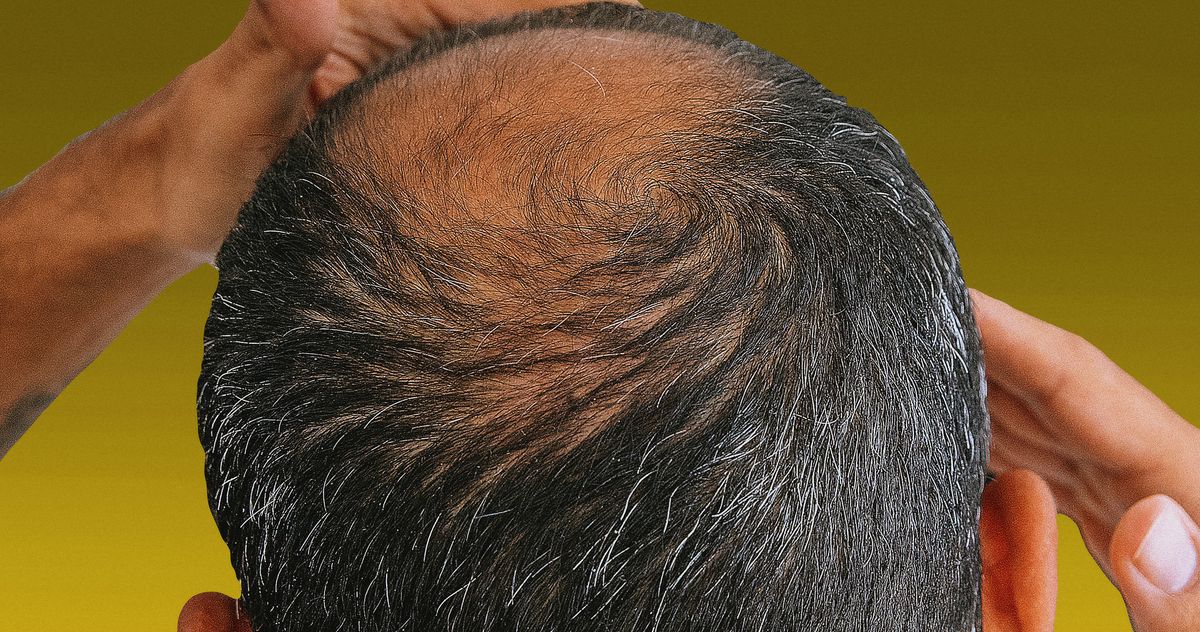

This is a entry level lawn edger. The hole (highlighted with a red arrow) where the wire goes in was designed from factory with a small diameter preventing you from buying larger diameter wires (better cut). So I figured I'd drill the hole to widen it. It worked as I was able to install larger diameter wires and cutting power drastically improved. However it created another issue. Now, I noticed that the wire will snap off at the hole junction. (when in operation). Normally wire degrades from the end of the wire (section in contact with grass) and as it gets shorter you have to rewind it to release more wire. But like I said, now it isn't what's happening, the whole wire will snap off where the red arrow points to. My guess is that by drilling the hole I made the edges less smooth, they were probably slightly curved before I messed with it. Looking for DIY suggestions on how to smooth out the edge to prevent the wire from snapping off. Even considered coating the wire with rubberized coating but doesn't seem really practical. Anyway, curious to see what you guys come up with Thanks on advance submitted by /u/PikachuOfTheShadow [link] [comments]

| This is a entry level lawn edger. The hole (highlighted with a red arrow) where the wire goes in was designed from factory with a small diameter preventing you from buying larger diameter wires (better cut). So I figured I'd drill the hole to widen it. It worked as I was able to install larger diameter wires and cutting power drastically improved. However it created another issue. Now, I noticed that the wire will snap off at the hole junction. (when in operation). Normally wire degrades from the end of the wire (section in contact with grass) and as it gets shorter you have to rewind it to release more wire. But like I said, now it isn't what's happening, the whole wire will snap off where the red arrow points to. My guess is that by drilling the hole I made the edges less smooth, they were probably slightly curved before I messed with it. Looking for DIY suggestions on how to smooth out the edge to prevent the wire from snapping off. Even considered coating the wire with rubberized coating but doesn't seem really practical. Anyway, curious to see what you guys come up with Thanks on advance [link] [comments] |

.jpg)

.jpg)

.jpg)