Replaced weird closet doors that came with my house with some DIY rattan doors on partial overlay hinges

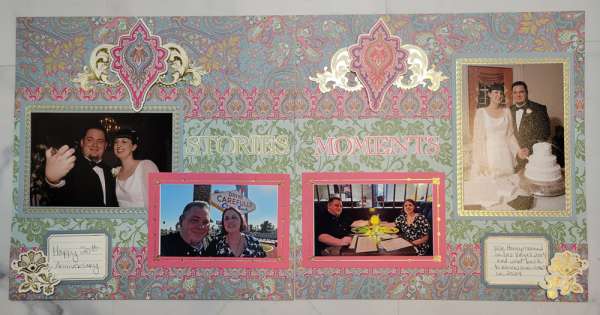

House came with the closed-in shelving with two sloppily cut closet doors on slides. They hardly worked and were a major eye sore. Goal of the project was to stick to only using leftover cabinet plywood and poplar boards from another project. I also wanted to expand/strengthen the shelves. Finally, there is (for some reason) a vent for our central air in there that we want to leave open. Decided against rerouting it into the hallway just to save time and money. I started by ripping out the doors and casing. I replaced with a mitered face frame out of 1x4 poplar with shims to make it plumb/level. This was probably the mistake that caused the most headaches. I should’ve just build the frame square and shimmed it to place with the hinges installed. I didn’t have a ton of space where I was working on this, so I didn’t think it was feasible. Next, I cut the shoe flush with the drywall and face frame so that I could case all four sides, which matches the rest of the house. I used an oscillating tool with a fresh blade, plus some patience. I installed shelves by building supports using the same 1x2 poplar I eventually used for the doors with the cabinet and the plywood boards. I cased in the vents with the scrap plywood until I ran out (which was fine anyway, since I intended to leave the vent exposed). You can see the original depth of the shelves on the second level of the first picture. By notching it around the vent, I also got a little nook for smaller items. Next, I picked six of the straightest 1x3 pieces of S4S poplar I could find in my leftover pile and built the cabinet frames. I measured as carefully as I could to get a 1/4” overlay on the face frame and a 1/8” gap in the center. Since everything was not perfectly square. I built the doors square to my longest measurements and decided to live with slight inconsistencies. I knew I could adjust the hinges anyway. I built the cabinet doors using half lap joints after cutting them to length with a miter saw. I don’t have a table saw, let alone a dado blade, so I used a Kreg crosscut jig with a circular saw to get 2.5” worth of kerfs at each end. I cut them to 3/8 depth before chiseling and filing. The nature of the crosscut jig meant it was very difficult to be precise, so I needed to do a considerable amount of sanding to get things mostly flush. Once I had them flush(ish) I clamped them together with wood glue and checked all four corners for square. I sanded and primed everything on a 120/220/400 progression. Painter friends told me I needed more “tooth” than 400 later, but whatever. It worked fine. I used BIN spray primer and Behr’s cabinet/trim enamel paint. Highly recommend that paint. I had previously used a cheap SW trim and door paint elsewhere and this was miles better. I hung the doors with half overlay soft close hinges I bought on Amazon. They were surprisingly simple to install, but I didn’t have a jig to bore the holes. Getting those holes to exactly 1/2” without poking the forstner bit through was nerve-racking. I did a final coat of paint on the doors and moldings now. Finally, I unclipped the doors and laid them butt together vertically so I could lay out the rattan and cut it to length. This took two tries because the original Amazon seller gave us 7 feet in our 10 foot roll. That was annoying. I soaked the rattan in warm water for 30 mins, let it air dry for 10 and then pulled it mostly taut as I stapled it. It tightens quite a bit as it dries, even pulling some of the staples halfway out. I hung the doors back up and am now picking out door pulls. I also spackled the little holes on the side where the stool went wider than the new casing. I’ll have to do a skim coat and some painting there still. TLDR: Made some mistakes along the way but it’s done and now I’m doing finishing touches. Project took a week but probably only 8-10 hours of actual work. AMA submitted by /u/whatigot989 [link] [comments]

|

TLDR: Made some mistakes along the way but it’s done and now I’m doing finishing touches. Project took a week but probably only 8-10 hours of actual work. AMA [link] [comments] |

-Baldur’s-Gate-3-The-Final-Patch---An-Animated-Short-00-03-43.png?width=1920&height=1920&fit=bounds&quality=70&format=jpg&auto=webp#)