Fixed my bowing basement walls. Still a lot more work to do.

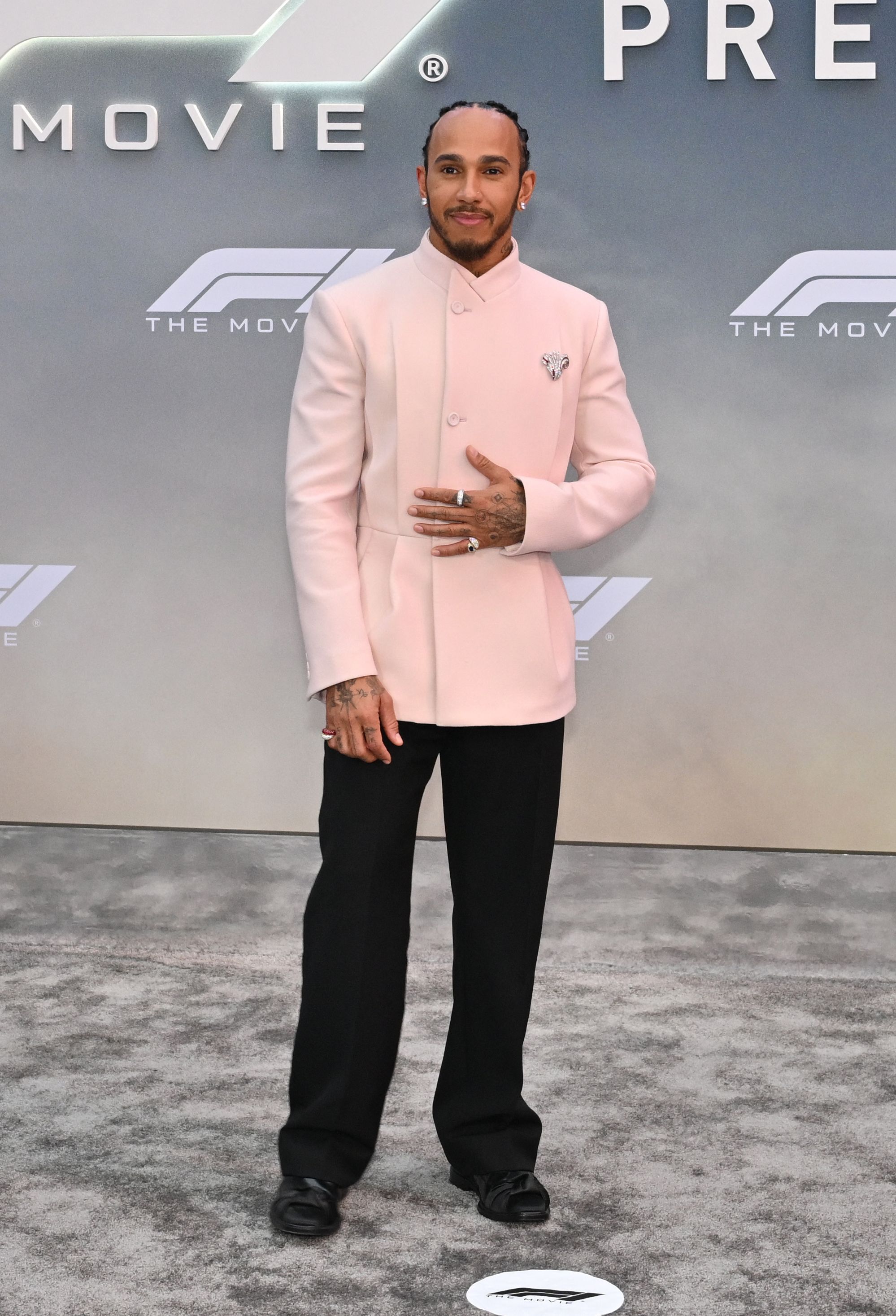

This is still a work in progress, but I thought I'd share my 'little' project with you guys. Note: Not the best pics, and I don't have any "before" pics, as I didn't actually plan on recording and posting this, but my dad is helping and he snapped some pics along the way, so I figured I'd share it. My 1956 ranch had some pretty bad foundation bowing on the south and east walls, with the lower 6 courses of the wall leaning inward about 1-1.5" from the base and the top 4 courses leaning outward. Also had some water intrusion in a few spots. I had the perimeter excavated so I could do waterproofing and replace the old drainage, so figured I might as well actually fix the walls while I had the opportunity. Previous owner had steel i-beams put in to brace the walls, but they weren't done right. Instead of being placed directly next to the base of the wall, they were set plum with the innermost bowing at each point, filled with mortar between the beam and block at the top and bottom, and the tops held in place with pieces of 2x12 lag bolted to the bottom of the floor joists. And the joints were tucked with N mortar (N mortar is not intended for structural use). They also laid new drainage only one one side of the house, and it was laid on top of the original drainage. None of this actually fixed any issues; it just (mostly) stopped it from getting worse. (If I knew who did all this crap, I would absolutely name and shame them.) First pic: We used 1/4" steel brackets bolted to the floor, 4x4" posts, 1/8" steel plates, and 6 ton bottle jacks. 2x8 "headers" are placed against the wall help distribute the jacking pressure across the height of the wall. Second pic: We chiseled out the horizontal mortar joint of the innermost bowed course, then slowly applied pressure across the jacks (the sound is slightly terrifying as the exterior joints begin to crack and loose mortar falls in the walls) until the wall was as close to plum as we could reasonably get it. You can see in the pic where the mortar used to be against the beam. Also, that chiseled out joint was originally about 1-1/8". Now it's 7/16". Third pic: After that, we filled the chiseled joint with S mortar, let it set, then (not pictured) chiseled out all the other areas that were previously filled with N mortar and refilled those with S mortar. Then we moved to the outside and did the same. Fourth pic: The steel beams were shimmed plum and proper joist blocking placed, then "shimmed" with 2x4 ripped to the appropriate width to fill the gap between beam and block. The width of the 2x4 "shim" is how far the innermost bowed area was pushed out from its starting position. Last pic: The corners were braced on the outside to keep from moving the entire wall out. We had 6' 2x8 headers on floor jacks at the east and west ends, running north/south. These are only snugged against the floor joists as they are strictly there as a safety precaution, not to actually relieve the downward pressure on the wall. So far, we've finished moving the walls and doing the mortar work. Next step is replacing some broken blocks in the SE corner. After that, we're installing a 30x48" egress window in place of the window in the first pic. Then, we can install the new drainage and waterproofing. Finally, we will backfill the excavated area with about 6' of stone and 2' of dirt, and install the egress well. As for costs, the materials and tools for fixing the walls came to ~$800. (The steel brackets and plates were from the scrap bin at work. The 2x8 are all repurposed from the front deck that we removed.) The egress window and well are ~$1.7k. Drainage and waterproofing materials are ~$1k. Excavation and backfill, plus some additional unrelated work with the loader, totals ~$5k (my loader/backhoe is too small for these tasks so I had to hire it out). For reference, I did get two local quotes for everything, and they were both right around $20k. The ~$11k saved here is going towards the next DIY projects: an all new HVAC system, then all new PEX plumbing and on-demand water heater. submitted by /u/Tenx82 [link] [comments]

| This is still a work in progress, but I thought I'd share my 'little' project with you guys. Note: Not the best pics, and I don't have any "before" pics, as I didn't actually plan on recording and posting this, but my dad is helping and he snapped some pics along the way, so I figured I'd share it. My 1956 ranch had some pretty bad foundation bowing on the south and east walls, with the lower 6 courses of the wall leaning inward about 1-1.5" from the base and the top 4 courses leaning outward. Also had some water intrusion in a few spots. I had the perimeter excavated so I could do waterproofing and replace the old drainage, so figured I might as well actually fix the walls while I had the opportunity. Previous owner had steel i-beams put in to brace the walls, but they weren't done right. Instead of being placed directly next to the base of the wall, they were set plum with the innermost bowing at each point, filled with mortar between the beam and block at the top and bottom, and the tops held in place with pieces of 2x12 lag bolted to the bottom of the floor joists. And the joints were tucked with N mortar (N mortar is not intended for structural use). They also laid new drainage only one one side of the house, and it was laid on top of the original drainage. None of this actually fixed any issues; it just (mostly) stopped it from getting worse. (If I knew who did all this crap, I would absolutely name and shame them.) First pic: We used 1/4" steel brackets bolted to the floor, 4x4" posts, 1/8" steel plates, and 6 ton bottle jacks. 2x8 "headers" are placed against the wall help distribute the jacking pressure across the height of the wall. Second pic: We chiseled out the horizontal mortar joint of the innermost bowed course, then slowly applied pressure across the jacks (the sound is slightly terrifying as the exterior joints begin to crack and loose mortar falls in the walls) until the wall was as close to plum as we could reasonably get it. You can see in the pic where the mortar used to be against the beam. Also, that chiseled out joint was originally about 1-1/8". Now it's 7/16". Third pic: After that, we filled the chiseled joint with S mortar, let it set, then (not pictured) chiseled out all the other areas that were previously filled with N mortar and refilled those with S mortar. Then we moved to the outside and did the same. Fourth pic: The steel beams were shimmed plum and proper joist blocking placed, then "shimmed" with 2x4 ripped to the appropriate width to fill the gap between beam and block. The width of the 2x4 "shim" is how far the innermost bowed area was pushed out from its starting position. Last pic: The corners were braced on the outside to keep from moving the entire wall out. We had 6' 2x8 headers on floor jacks at the east and west ends, running north/south. These are only snugged against the floor joists as they are strictly there as a safety precaution, not to actually relieve the downward pressure on the wall. So far, we've finished moving the walls and doing the mortar work. Next step is replacing some broken blocks in the SE corner. After that, we're installing a 30x48" egress window in place of the window in the first pic. Then, we can install the new drainage and waterproofing. Finally, we will backfill the excavated area with about 6' of stone and 2' of dirt, and install the egress well. As for costs, the materials and tools for fixing the walls came to ~$800. (The steel brackets and plates were from the scrap bin at work. The 2x8 are all repurposed from the front deck that we removed.) The egress window and well are ~$1.7k. Drainage and waterproofing materials are ~$1k. Excavation and backfill, plus some additional unrelated work with the loader, totals ~$5k (my loader/backhoe is too small for these tasks so I had to hire it out). For reference, I did get two local quotes for everything, and they were both right around $20k. The ~$11k saved here is going towards the next DIY projects: an all new HVAC system, then all new PEX plumbing and on-demand water heater. [link] [comments] |